Ever-Power Group

Sprocket

Sprocket

ever-power

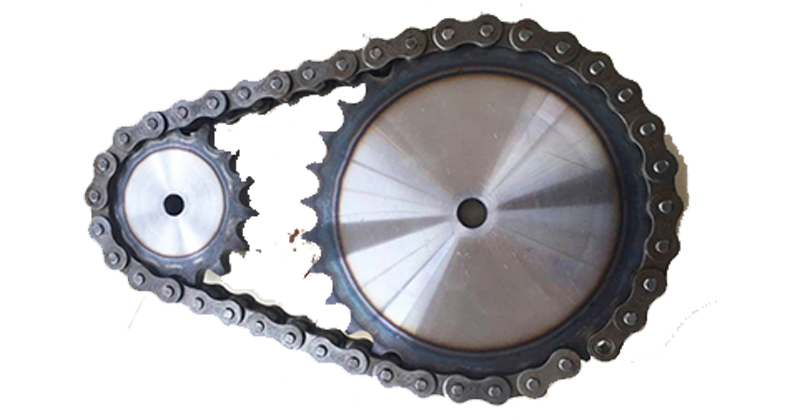

What is sprocket

Sprocket is a kind of wheel with cogged chain teeth, which is used to mesh with blocks with accurate pitch on chain link or cable. Sprocket is widely used in chemical industry, textile machinery, escalator, wood processing, three-dimensional garage, agricultural machinery, food processing, instrumentation, petroleum and other industries of mechanical transmission.

sprocket

Structural Design

The tooth profile of sprocket must ensure that the chain can enter and exit the meshing smoothly, reduce the impact and contact stress of the chain link as much as possible, and be easy to process.

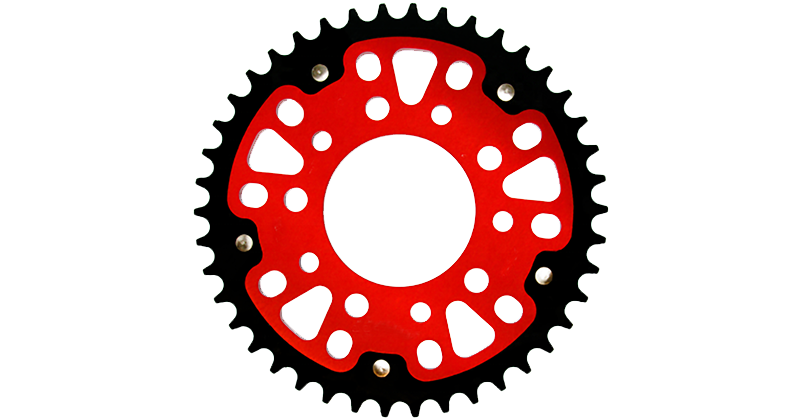

Sprocket material should ensure that the teeth have enough strength and wear resistance, so the sprocket tooth surface is generally heat treated to achieve a certain hardness.

Seiko manufacturing

High quality material preparation

High precision detection

Roller hobbing

Maintenance

- The tightness should be appropriate

- There is no swing and skew in the installation

- At the same time, replace with a new sprocket

- Remove the link, but it must be even

- Add lubricating oil in time

- The old sprocket cannot be mixed with some new ones

- Kerosene or diesel oil cleaning

EPT

sprocket

Usage Method

As a new gear product, the transmission speed of sprocket is high. In its specific application process, because of the advantage of high speed, the noise is very small, which is also conducive to achieve a good processing environment. Sprocket in its application, not only the installation accuracy is relatively high, but also the machining accuracy is very ideal, which can save a lot of trouble for future maintenance work. Moreover, the advantages of compact sprocket structure make it have larger transmission ratio, and its service life is also relatively high.

Click Details

Read More